Essatex Industries presents a picture of the perfect VERTICAL SETUP spread over two units. In order to achieve and maintain high quality control and to retain strict focus on specialization, the production units have been decentralized into multiple units.

Weaving

Weaving at ESSATEX INDUSTRIES

At Essatex Industries, the weaving stage begins with high-precision yarns loaded onto advanced shuttle-less looms in a purpose-built facility. Multiple blends such as 100% cotton, polyester and poly-cotton are interlaced into fabrics using patterns like plain, twill and satin weaves.

Their fleet of 86 Sulzer looms (85″ to 153″ width) ensures large-width production and consistent fabric density. Throughout the weaving operation, yarn preparation and beam forming are tightly controlled to maintain high quality and reduce defects. Finally, the freshly woven greige fabric is inspected and forwarded for pretreatment and downstream processes.

Designing

Designing at ESSATEX INDUSTRIES

At Essatex Industries, the design studio begins by analysing global trend cues and client briefs to develop on-point motifs, colour stories and fabric textures. The in-house creative team uses CAD/CAM systems and digital ink-jet scanners to translate concepts into repeatable fabric patterns.

These designs are then plotted into film or electronic formats and prepped for rotary or digital printing machines. This stage also involves sampling of colour-ways and finishes, enabling customers to visualise and approve the final look. Once approved, the patterns and colourways are locked and handed over to production for printing, dyeing and finishing.

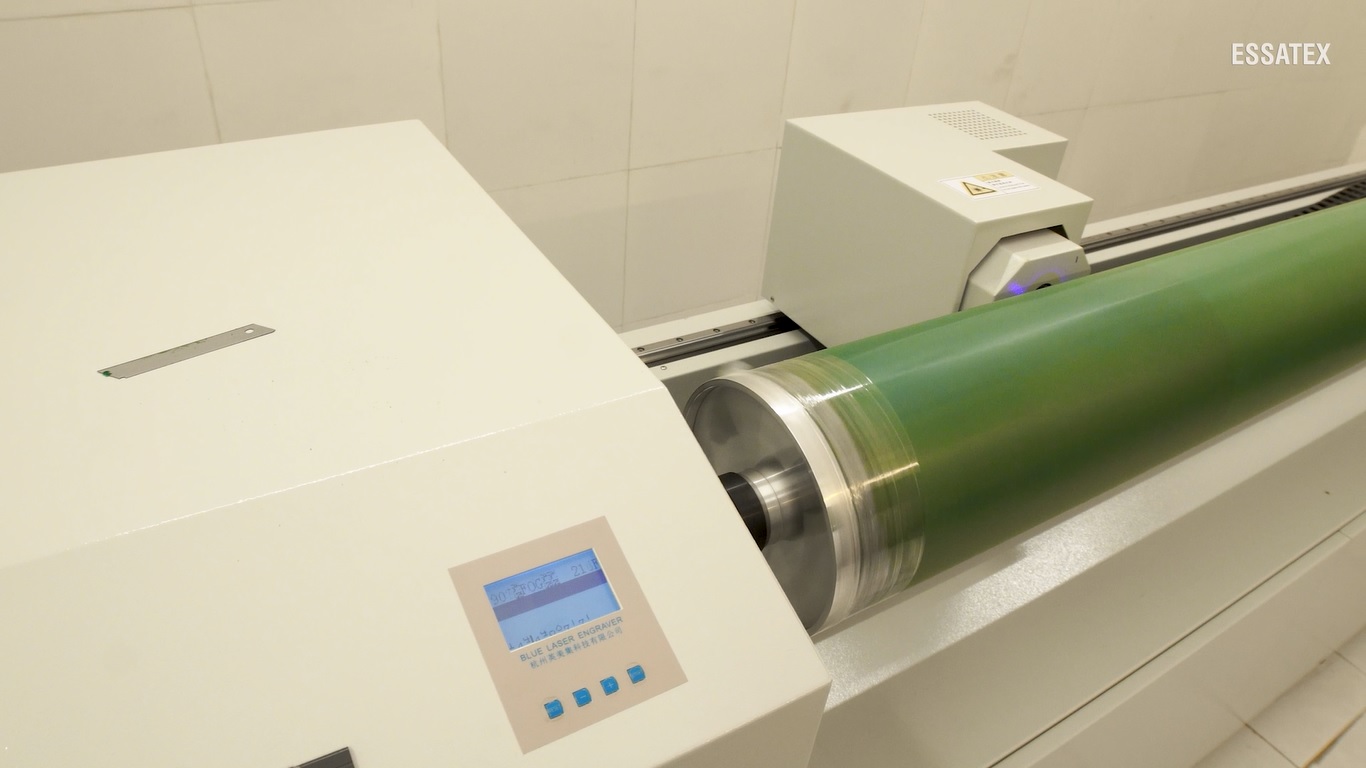

Engraving

Engraving at ESSATEX INDUSTRIES

At Essatex Industries, the engraving step involves applying fine, detailed patterns onto fabric surfaces using specialized engraving rollers or laser-etched tooling to create texture and depth. After the fabric is prepared and cleaned, the engraved tools press or engrave designs onto the material, transferring raised or recessed motifs that enhance the tactile feel and visual richness.

This process is precisely aligned with the design film prepared earlier, ensuring repeat accuracy and registration of the pattern. Once engraving is complete, the fabric moves to fixation or curing to stabilise the embossed or engraved effect before subsequent finishing treatments. The result is a premium finish, adding upscale texture to the textile for decorative, home-linen or upholstery applications.

Processing

Processing at ESSATEX INDUSTRIES

At Essatex Industries the processing stage encompasses pretreatment, dyeing, printing and finishing under one purpose-built unit equipped with state-of-the-art machinery. Greige fabric is first singed and desized to remove impurities and sizing agents, enabling better absorption of dyes and print inks.

The fabric is then dyed or printed on high-capacity rotary machines (up to 14 colours and 320 cm width) and subsequently cured and stentered to fix colour and ensure dimensional stability. In the finishing zone, fabrics undergo calendar treatments, weft-straightening and mechanical softening to attain desired hand-feel, performance (e.g., water-repellence or coating) and visual quality. The integrated processing setup gives Essatex flexibility in producing both plain and high-design fabrics for home-textile, upholstery and export markets.

Printing

Printing at ESSATEX INDUSTRIES

At Essatex Industries the printing department uses a high-capacity rotary printing machine capable of 14 colours on fabrics up to 320 cm wide, allowing bold, large-width patterning.

After the design layout is finalised and engraving prepared, the fabric is fed through the rotary machine where each colour is transferred with precision registration aligned to the design repeat.

Post print, fabrics move immediately to curing and stenter units to fix the inks, stabilise the fabric structure and ensure fastness of the print. The process supports both home-textile and upholstery widths, enabling large-scale runs as well as varied design repeats, under full in‐house control of design, engraving, printing and finishing.

Laboratory

Laboratory at ESSATEX INDUSTRIES

In the laboratory division at Essatex Industries, fabrics are subjected to rigorous testing for yarn strength, cloth density, colour fastness, and dimensional stability to ensure compliance with international export-standards.

Separate fully-equipped labs sit within both the weaving and processing units, enabling real-time quality control at every stage. Before the bulk production begins, trial samples from weaving, printing or finishing are analysed for defects, shrinkage behaviour and output consistency, thereby reducing downstream rejects. The lab team uses computerized testing instruments to track statistical process control metrics and issue go-/no-go decisions for batches. Finally, the lab data is archived and shared with design, production and finishing teams so that any corrective actions can loop back into the process, maintaining high standards and delivering customer satisfaction.

Finishing

Finishing at ESSATEX INDUSTRIES

At Essatex Industries, the finishing department adds the final touch to fabrics, enhancing their appearance, feel, and performance characteristics. Fabrics emerging from dyeing or printing are passed through advanced stenter machines, calenders, and softeners to achieve uniform texture, shrinkage control, and dimensional stability. Specialized treatments such as peach finish, water repellency, and coating are also applied based on customer requirements. Continuous monitoring ensures even surface smoothness, correct GSM, and the desired hand-feel. The process concludes with careful inspection, rolling, and packaging—ensuring every meter meets Essatex’s premium export-quality standards.

Stitching

Stitching at ESSATEX INDUSTRIES

At Essatex Industries, the stitching unit transforms finished fabrics into high-quality made-ups such as bed linens, curtains, and home furnishings. The department is equipped with modern industrial sewing machines, overlock and hemming systems that ensure precision stitching and durability. Skilled operators follow detailed specifications and pattern layouts to produce consistent seams and fine finishing. Each product undergoes in-line quality checks for thread tension, measurement accuracy, and workmanship standards. The final stitched items are pressed, labelled, and packed according to customer requirements—ready for global shipment under the Essatex quality promise.

Quality Control

Quality Control at ESSATEX INDUSTRIES

At Essatex Industries, the Quality Control (QC) department plays a critical role in ensuring that every fabric and finished product meets international standards. QC teams inspect raw materials, in-process fabrics, and final stitched items for defects in colour, texture, dimensional accuracy, and stitching quality. Advanced testing equipment and standardized procedures are used to measure colour fastness, strength, shrinkage, and hand-feel. Any deviations are immediately flagged, and corrective actions are implemented to maintain consistent product quality. Detailed records of inspections are maintained for traceability and continuous improvement. This rigorous QC process ensures that every Essatex product delivered to customers is defect-free and of premium export quality.

Packing

Packing at ESSATEX INDUSTRIES

At Essatex Industries, the packing department ensures that every finished product is presented neatly and securely for shipment. After final inspection, stitched items are folded, pressed, and packed according to buyer specifications—whether in retail-ready poly bags, cartons, or bulk packaging. Advanced pressing and vacuum systems maintain product freshness and crease-free appearance. Each package is barcoded and labelled for easy identification, ensuring traceability throughout the supply chain. The department maintains strict hygiene and handling standards so that every Essatex product reaches customers in pristine, export-quality condition.

Premium Quality Fabrics

Essatex Industries delivers high-performance textiles crafted with precision, ensuring durability, comfort, and superior finish.

Innovative Manufacturing

Our state-of-the-art facilities combine advanced technology with expert craftsmanship to meet global textile standards.

Sustainable Practices

Committed to eco-friendly production, Essatex prioritizes responsible sourcing and environmentally conscious processes.