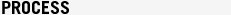

Essatex Industries presents a picture of the perfect VERTICAL SETUP spread over two units. In order to achieve and maintain high quality control and to retain strict focus on specialization, the production units have been decentralized into the following units:

|

Weaving

Pretreatment

Ink Jet Designing

Printing

Dyeing

Finishing

Coating & Flocking

Wadding

Quilting

Stitching

Quality Assurance |

|

Weaving

The units have 86 Sulzer Shuttle less looms having 85 to 153 inches including Dobby. These machines operate in a new custom built weaving facility supported by the most modern yarn preparation equipment and are comparable with the finest available fabric preparation equipment anywhere in the world.

Major Blends: 100% cotton, 100% polyester and polycotton

Major Weaves: Plain, satin, twills, drills, canvas, momie, thermal, waffles and jacquards

Operations – Pretreatment, Printing, Dyeing, Finishing

Pretreatment, Printing, Dyeing, Finishing

The processing unit is equipped with a wide range of state of the art machines which gives Essatex Industries a flexible processing possibility and an edge over its competitors.

EssaTex Industries has 1 sophisticated rotary printing machine capable of printing up to 14 colours on fabrics as wide as 320 cm with repeat option 64cm, 82 cm, 91 cm & 101 cm and capable of dyeing upto 320 cm as well as capable of coating & flocking upto 300 cm.

Processing and Finishing Machinery

- Calender - Kuster

- CAD/CAM System

- Film Plotter

- CST Inkjet Scanner

- Rotary Printing including 14 colour and upto 320 cm width

- Singeing & Desizing

- Curing

- Stentors - Babcock

- Washing and Drying Range

In the finishing section, modern stenters are fitted with the most sophisticated electronic weft straighteners which achieve perfect finishes. Final touch to the fabrics is given on different calendars according to the requirements of the buyers.

Top

In the finishing section, modern stenters are fitted with the most sophisticated electronic weft straighteners which achieve perfect finishes. Final touch to the fabrics is given on different calenders according to the requirements of the buyers.

Operations – Design & Styling

Design & Styling

Essatex Industries’ design studios are staffed with experienced artists with capabilities to meet the most stringent requirements in design and to adapt to different color ways to meet the requirements of each individual country.

Top

Quality Assurance

Essatex Industries maintains strict quality control and possesses computerized testing for strength of yarn, density of cloth and fastness of colors. Fully equipped labs are installed separately in areas of weaving and processing.

The quality control personnel conduct pre-inspection of goods at different stages to maintain international standards and to ensure customer satisfaction on a regular basis.

Top

Wadding

Top Warping

Top |